GSL ENERGY 21700 battery cell latest manufacturers

2019 New Best Bechargeable Battery 3.7V 4000mAh 21700 Battery For Tesla Powerwall

1. Application Scope

This product specification describes product performance indicators of Lithium-ion battery produced by SHENZHEN GSL TECH CO LTD.

2. Model

ICR21700-4000mAh-3.7V

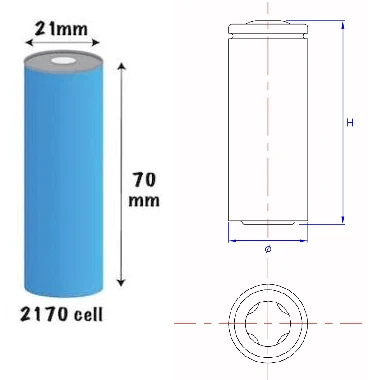

3. Appearance and Dimension

Item | Dimension (mm) |

Diameter | 21±0.1 |

Height(H) | 70±0.4 |

4. Major Technical Parameters

No. | Item | Standard | Note | |

1 | Standard Capacity | 4000mAh | 0.5C,(current value of 2200mA at 1C) | |

2 | Capacity Range | 3950~4250mAh | 0.5C | |

3 | Standard Voltage | 3.7 V | ||

4 | Alternating Internal Resistance | ≤60mΩ | with PTC | |

5 | Charge Conditions | Cut-off Voltage | 4.2±0.05V | constant current charge to 4.2V at 0.5C, constant voltage charge to stop until 0.01C mA |

Cut-off Voltage | 0.01C | |||

6 | Discharge Cut-off Voltage | 2.75V | ||

7 | Cycle Characteristic | 1000 times | 100% DOD, the residual capacity is no less than 70% of rated capacity at 1C rate. | |

8 | Max. Continuous Discharge Current | 3C | ||

9 | Pulse Discharge Current | 5C, 5s | ||

10 | Working Temperature | Charge:0°C~55°C Discharge:-20°C~60°C | ||

11 | Storage Temperature | -20°C ~ 45°C | ||

12 | Battery Weight | 65 g (Approx.) | ||

5. Characteristics Curves

6.Safety Characteristics

NO | Item | Test Method | Standard |

1 | Overcharge | After normal charge, test the batteries’ initial state and capacity. Charge to 10.0V at 3C, then charge at CV mode to 0.01C. Observe battery’s variation of appearance. | No explosion, No fire. |

2 | Over Discharge | After normal charge, test the batteries’ initial state. When the batteries are normal, Discharge to 0V at 0.5C. Observe battery’s variation of appearance. | No explosion, No fire. |

3 | External Short-circuit | After normal charge, test the batteries initial state, Keep the battery into explosion protection cover, short-circuit the positive and negative terminals directly (general resistance shall be less than or equal to 50mΩ). Stop the test when the temperature falls to 10℃ lower than the peak value. Observe the variation of the batteries’ appearance and temperature. | No explosion, No fire. |

4 | Thermal Abuse | Test the batteries’ initial state and capacity. Standard charge. Put battery into oven, increase the temperature to 130±2℃ at rate of (5±2℃) /min, and keep it for 30min. Observe the variation of batteries’ appearance. | No explosion, No fire. |

5 | Drop | After normal charge, test the batteries’ initial state and capacity. Then let it fall from a height of 1m (the lowest height) to a smooth cement floor, twice. | No explosion, No fire. |

6 | Heavy Impact | A diameter of 15.8 mm steel rod is placed in the middle of the fully charged battery, then the weight of 10Kg hammer from 1.0m height free falls to the battery upper. | No explosion, No fire. |

7 | Extrusion Test | Place the battery in between the pressing surface of extrusion apparatus, parallel the axes of cylindrical battery to the pressing surface, and gradually increase pressure up to 13KN, keeping the pressure for 1min. | No explosion, No fire. |

SAFETY

Passed the below abuse and safety test-short-circuit, dropping, nail penetration, impact, crush, thermal shock, over-charge,over-discharge: no fire, no explosion with stable chemical structure.

APPLICATIONS

1.Energy Storage

--Solar-Wind Power System / City Grid (On/Off) / Community and Family

2.Back-up System and UPS

--Telcom Base / CATV system / Computer Server Center / Medical Instrumnt / Military Equipment

3.Other Applications

--Security and Electronics / Mobile POS, Mining Lihgt / Torch / LED Light / Emergency Light

--RV Motorhome /Golf Carts Battery / Boat Marine Yachts / Electric Skateboard

--LED Backup / Engine Starting Battery,etc.

WHY CHOOSE US ?

1.Experience--More than 12 years Specialized in lithium battery, Gold Supplier on Alibaba.

2.Certification--CE,UL,MSDS,Test Report from National Center For Quality Supervision and Inspection of Battery Products approved.

3. Quality Control-- 37 production process,7 steps quality check to promise stable quality and high reliability for you.

4. Best Material-- Insist on choosing top quality cell, material and accessories,lithium battery last longer time.

5. Fresh battery-- All battery is fresh Production.

KS ENERGY is focused on manufacturing, R&D and sales for safe Lithium battery and solutions. With the registration and certification of CE, SGS, ROHS. Striving to grow into a global leading lithium battery supplier, KS ENERGY has been working hard on researching and developing new process technology to make our lithium battery more affordable and able to meet the rapidly growing market demands.

As a sub-factory of GSL GROUP, KS ENERGY is specializes in clean and new energy on lithium ion battery products.

Welcome To Visit Our Factory

Through years development and experienced international sales team in Shenzhen, KS ENERGY green solar and lithium battery products have been sold to clients all over the world.

Since 2006, KS ENERGY has maintained a corporate philosophy that is characterized by entrepreneurship, innovation, competition and transcendence. Today KS has established a solid foundation in two major industries: photovoltaic and Lithium, with its four production bases in Shangdong, Zhejiang, Sichuan, Guangdong.

KS ENERGY partners with customers to provide complete energy storage solutions that enable the rapid development and delivery of innovative products that meet demand in both existing and emerging markets.

--Professional pack module design on cylindrical and Prismatic design.

--Fast Production and Delivery time.